I’ve had a few situations come up over the past year where clients were confused over the concept that all woods take stain differently. This holds true between different species, between trees of the same species, between boards milled from the same tree, and even within a single board. I figured I’d write a little something about this topic to illuminate those of you that are unfamiliar.

Selecting the right wood for a project needs to be based upon the goal of achieving balance between the desired appearance of the finish and the required strength of the substrate.

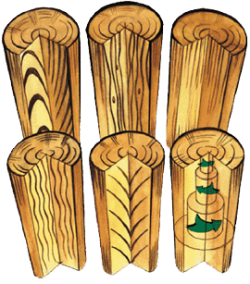

Know Your Grains

The grain of a wood is largely responsible for its appearance. The grain is the result of how the tree grows along the main axis of its trunk. If it grows straight, it is “straight grained” wood. If the cells deviate from the main axis of the tree as it grows, the result is “cross grained” wood. Further, if the tree twists as it grows, it produces “spiral grained” wood. Trees with an undulating cell structures result in irregular or “wild grained” wood.

Texture also plays into appearance. This refers to the relative size of the wood’s cells, or its porosity. Woods with small, closely spaced cells produce a fine texture; a course texture is the result of relatively large cells.

Differences Between Softwood and Hardwood

Contrary to popular belief, the strength of wood has nothing to do with whether it is considered a “softwood” or a “hardwood” – this refers to the botanical grouping of the wood rather than its physical properties. However, the majority of hardwoods are indeed harder than softwoods. Strength is actually determined by density of the wood, which can be figured by driving a metal ball halfway into the wood’s surface. The force used is recorded in pounds; the higher the number, the stronger the wood.

Examples of Softwood

Softwoods come from coniferous trees such as cedar and pine. They are somewhat yellow or reddish in color, and since they grow fast and straight, they are usually less expensive than hardwoods. Softwoods are primarily used for building construction and joinery.

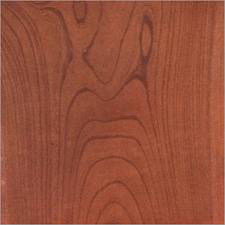

Types of Hardwood

Hardwoods come from deciduous trees and include such species as ash, birch, cherry, mahogany, maple, oak, poplar, teak and walnut. In our finishing business, we work primarily with hardwoods. Although they are more expensive, their variety in color, texture and grain make for beautiful cabinetry and furniture – so long as you appreciate that variety!

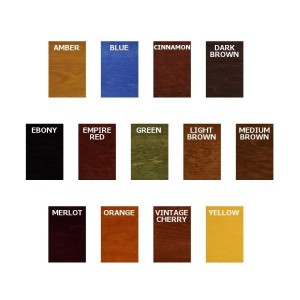

Wood Stain Options

Now that we understand the properties of the substrate (wood), we need to understand the properties of the finishing product (stain). A wood stain is a colorant that is suspended or dissolved into a vehicle such as water, alcohol, or a finishing agent (shellac, lacquer, varnish, polyurethane). Colorants can be pigments, which are opaque, dyes, which are translucent, or a combination of both. Pigments are large particles suspended in the vehicle while dyes are microscopic crystals that dissolve in the vehicle.

Tips for Choosing the Perfect Wood and Wood Stain Combination

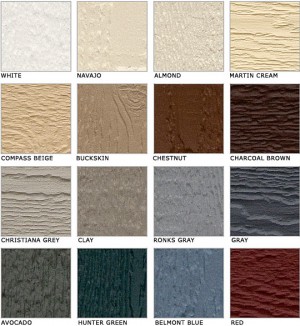

The overall color and shade of the finished product is the result of a combination between the properties of the wood and the properties of the stain. Because every piece of wood is so unique, wood stained finishes will always have some sort of inherent variation. This is why selecting the right wood and the right product is critical in order to closely approximate the desired aesthetic. Here are a few more points to consider:

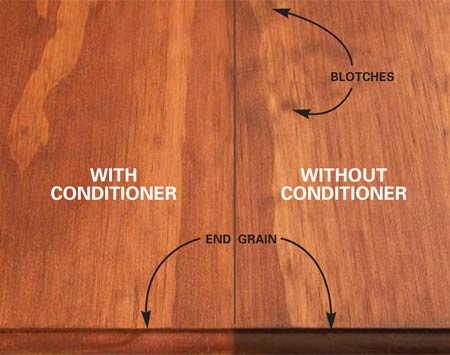

- Highly porous wood, or portions of a board that are more porous than others, will absorb more stain, thus darkening considerably in those areas.

- Finely grained woods have pores too small for pigments to attach themselves to without the help of a binding agent. Dye stains, however, will easily color finely grained wood.

- Aged wood absorbs stain better than “green” lumber. New lumber can also sometimes have a wax-like sealant put on it at the mill. This will prevent the wood from accepting stain if not properly prepared.

- Woods that have been heavily subjected to strippers or washed down with solvents will have an increased open grain and accept more stain than normal.

- Different species take stain better than others. For example, a medium-dark stain tends to look blotchy on maple, but shows more consistent coloration on cherry.

In addition, technique can have a major affect on the appearance of the finished product. Following proper methods of preparation, properly conditioning the surface when necessary, sanding evenly between coats, knowing how long to keep the product on the substrate, and proper application of a protective top coat are all important things to factor into the process.

As you can see, the art of wood finishing is a complex thing. For best results, you should always rely on a professional contractor to complete the project. The Ragsdale crew has been at it for 35 years. We are highly experienced, extremely knowledgeable in product technology, and run a totally legitimate operation. If you’re looking for the best finish with the least amount of risk, you know where to find us.